Introduction to Occupational Health Hazards

Subtopic:

Hazard Prevention and control

Hazard prevention involves workplace programs specifically aimed at stopping work-related injuries and illnesses from happening.

Hazard control refers to putting in place policies, rules, ways of doing things, and physical changes to get rid of or lessen dangerous risks.

Hazards are things that can harm workers, leading to injuries, sickness, or accidents.

Identifying Hazards: This is the first step in assessing risks. It means spotting and noting down potential dangers that might be present in a particular setting.

Hazard identification is the process of finding, locating, and recording anything that has the potential to cause harm, damage, injury, or negative health effects. This step is about recognizing what dangers could be present in a general sense.

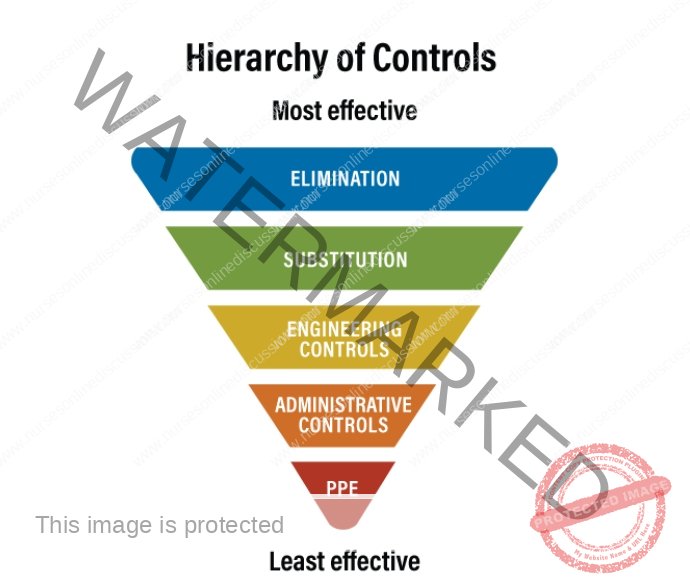

Methods of hazard control/Hierarchy of Controls at the workplace

There are different ways to prevent and control hazards, ranked by how well they work. Methods higher up in the ranking are more effective. The hierarchy of controls is:

Elimination: Removing the Risk (Level One): This is the most effective method, as it completely gets rid of the hazard from the workplace. For instance, promptly wiping up spills on the floor or upgrading old, unsafe wiring removes the chance of slips, trips, or electrical dangers.

Substitution: Replacing the Risk (Level Two): This is the next best method, involving replacing a dangerous hazard with a safer one. An example is using disposable needles instead of reusable ones to lower the risk of infection. It’s important to check for new risks after making a substitution.

Isolation: Separating the Risk (Level Three): This method involves keeping workers away from the hazard using barriers or distance. For example, placing noisy machinery in a separate enclosed room and using remote controls keeps workers safe from injury. Another example is using specific rooms to isolate patients with infectious illnesses.

Engineering controls: Physical Safety Features (Level Four): This involves designing and installing extra safety features on workplace equipment. These are physical changes to equipment or the work area that reduce exposure to dangers. Examples include installing air ventilation systems in areas with harmful dust or gases, or fitting safety railings on elevated walkways to prevent falls.

Administrative controls: Rules and Procedures (Level Five): These are rules, policies, procedures, or training programs meant to change how workers act or do their jobs to avoid or lessen hazards. For example, providing training on the correct way to operate machinery, or adjusting work schedules to reduce time spent in risky areas helps prevent mistakes or tiredness.

Personal protective equipment (PPE): Protective Gear (Level Six): These are items workers wear to protect themselves from hazards, like safety helmets, ear protection, gloves, and face masks. This is the least effective on its own because it doesn’t remove or reduce the hazard itself. It only protects workers if an incident happens. Therefore, PPE is best used alongside other control methods and as a final measure

Considerations for Effective Control and Prevention of Hazards

Include workers: They often understand workplace hazards and their control best.

Evaluate control options: Use the “hierarchy of controls” to choose the most effective, long-term solutions, prioritizing engineering controls over administrative controls and PPE.

Use a hazard control plan: This plan should outline how chosen controls will be implemented and who is responsible.

Plan for non-routine tasks and emergencies: Develop procedures for controlling hazards during maintenance, repairs, and emergencies like fires or explosions.

Implement controls: Put the selected controls into practice according to the hazard control plan and monitor their effectiveness.

Verify effectiveness: Track implementation progress, inspect and evaluate installed controls, and perform routine preventive maintenance.

Prevention of Occupational Health Hazards

There are three tiers for preventing workplace health risks: primary, secondary, and tertiary prevention.

Primary Prevention

Primary prevention focuses on stopping exposure to dangers from the outset. This can be achieved through various actions:

Workplace Health Awareness: Informing employees about workplace risks and safe practices.

Pre-Work Health Checks: Evaluating potential employees for pre-existing health issues that could increase their vulnerability to workplace hazards.

Implementing and Upholding Safety Standards: Establishing and ensuring adherence to regulations and practices that create a safe work environment.

Supplying Protective Gear: Providing workers with necessary Personal Protective Equipment (PPE) to shield them from hazards.

Designing for Safety: Modifying the workplace setup to lessen or remove hazards.

Secondary Prevention

Secondary prevention aims to find and address health issues early on, preventing them from worsening. This involves:

Routine Health Monitoring: Regularly tracking workers’ health for indications of work-related health problems.

Targeted Health Testing: Screening workers for specific health issues potentially linked to their jobs.

Providing Care: Offering treatment to workers for diagnosed occupational health problems.

Tertiary Prevention

Tertiary prevention focuses on minimizing the impact of occupational health problems that have already occurred. This can be achieved through:

Return-to-Work Support: Assisting workers who have been impacted by occupational health issues to resume their jobs.

Financial Aid: Providing compensation to workers who have suffered injuries or disabilities due to workplace health problems.

Preventing Recurrence: Implementing measures to stop further injury or disability in affected workers.

Occupational Hazard Assessment

Occupational hazard assessment is the regular review of work areas, tools, and personnel to ensure occupational hazards are prevented.

Importance of Occupational Hazard Assessment

This evaluation is crucial for:

The Employer

The Employees

The Community

Employer:

Meeting Legal Requirements: Occupational hazard assessments help employers adhere to laws and regulations related to workplace safety, showing their dedication to a safe environment.

Managing Potential Dangers: Assessing workplace hazards allows employers to pinpoint potential risks and put suitable controls in place. This proactive stance lowers the chance of workplace incidents and related financial burdens.

Boosting Efficiency: A safe and healthy workplace improves employee well-being, job satisfaction, and morale. By addressing risks, employers create a supportive environment that can lead to better output and efficiency.

Building Trust and Image: Employers who prioritize hazard assessment demonstrate their commitment to employee safety and welfare, improving their reputation and fostering trust among staff and stakeholders, making it easier to attract and keep skilled employees.

Example: A manufacturing firm regularly assesses its production area. One assessment revealed risks from older machines. Consequently, the employer invested in updated equipment to enhance worker safety and performance. This action not only reduced accident risks but also highlighted the employer’s dedication to employee well-being and safety compliance.

Employee:

Ensuring Personal Safety: Hazard assessments prioritize worker safety by identifying and addressing potential dangers, allowing employees to work confidently knowing their well-being is valued and risks are being managed.

Promoting Health: Identifying and controlling risks through assessments promotes worker health. By lessening exposure to workplace risks, employees are less prone to developing work-related illnesses or injuries, leading to better overall health.

Fostering Engagement: Including employees in hazard assessments allows them to actively participate in maintaining a safe workplace, contributing their insights and fostering a sense of ownership over safety.

Increasing Confidence and Satisfaction: Employees who feel secure at work have higher job satisfaction and engagement. Hazard assessments contribute to this confidence, improving employee retention and loyalty.

Example: In a construction firm, hazard assessments are done before each project. One assessment identified potential fall risks, leading to the implementation of harnesses and guardrails. By involving employees in the assessment and addressing their concerns, the company empowers its workers, building confidence and job satisfaction.

Community:

Safeguarding Public Well-being: Occupational hazard assessment benefits the community by ensuring workplaces operate safely for the wider public. Preventing workplace accidents contributes to overall community well-being.

Protecting the Environment: Hazard assessments often include evaluating the environmental impact of work processes. By identifying and controlling hazards that could harm the environment, they contribute to responsible practices.

Enhancing Public Image: Companies that prioritize hazard assessment demonstrate responsible business practices, fostering community trust and potentially attracting local support.

Example: An oil refinery conducts regular hazard assessments to ensure operational safety. One assessment identified risks of chemical spills impacting the environment and nearby areas. The refinery invested in better containment and strict protocols to prevent such incidents. By prioritizing hazard assessment, the company protects the community and builds goodwill.

Methods of Hazard Identification, Prevention, and Control

Human Resource

Pre-Employment Health Evaluation: This assessment serves three purposes:

To determine if an applicant is suitable for a specific role, considering potential risks to their health and safety, as well as to others.

To identify any existing, but not yet apparent, health conditions.

To establish a baseline health record for future comparisons.

Regular Health Check-ups: These are conducted to identify any negative health trends caused by work.

Specific Medical Evaluations: These are necessary before a worker returns after illness, following indications they are struggling with their work, and for those with ongoing health conditions.

Equipment and Workplace/Site

Regular Equipment Checks and Maintenance: This helps spot and fix potential dangers before accidents occur.

Repairing and Replacing Tools: Ensuring equipment is in good condition and doesn’t pose a risk to workers.

Providing Standard Operating Procedures (SOPs): Clear instructions on how to use equipment safely.

Regular Emergency Drills: Helping employees learn how to react effectively in emergencies.

Providing Protective Clothing: Supplying items like safety glasses, helmets, and gloves to protect workers.

Installing Warning Signs and Restricting Access: Keeping workers safe by highlighting dangers and limiting access to hazardous areas.

Standard Employee Training: Training before starting work and when using new equipment to ensure safe operation and hazard identification.

Installing Fire Safety Equipment: Helping to stop fires and protect workers from burns.

Providing Sanitation Facilities: Offering handwashing stations to prevent the spread of infection.

Designated Emergency Meeting Points: Clearly marked areas for workers to gather during emergencies.

Steps in Occupational Hazard Assessment and Identification

Occupational hazards are potential sources of damage, harm, or negative effects on worker health and safety, or the environment. Occupational hazard assessment and identification involves finding, recognizing, and describing workplace hazards, and evaluating their associated risks to prevent or reduce work-related injuries, illnesses, and fatalities.

The following steps can be used for occupational hazard assessment and identification:

Gathering Existing Hazard Information:

Before looking for hazards, it’s useful to collect and review existing information from internal and external sources, such as:Safety inspection records.

Records of past incidents, injuries, near misses, complaints, or suggestions.

Safety Data Sheets (SDS), labels, manuals for hazardous materials or equipment.

Relevant regulations, standards, and guidelines.

Reports from professional organizations, research bodies, or government agencies.

Feedback from workers, supervisors, safety committees, or unions.

This information should be reviewed with workers to identify potential hazards and those who might be exposed, helping focus inspections.

Workplace Safety Inspection:

Even with existing information, regular workplace inspections are essential to identify new or overlooked hazards from changes in work areas, processes, or equipment. Hazards can arise from poor maintenance or inadequate training.

Workplace inspections involve observing conditions and work activities to identify potential harm to workers or the environment using methods like:Visually scanning the workplace for obvious hazards like spills or broken equipment.

Talking to workers about their concerns regarding their work.

Using checklists to ensure thorough coverage.

Documenting observed hazards with notes or photos.

Workers are valuable internal resources for identifying hazards, especially with training. They have direct knowledge of their tasks and may spot hazards others miss. Their involvement increases awareness and participation in safety.

Identifying Hazards in Emergencies and Unusual Situations:

Besides routine hazards, it’s vital to identify risks during emergencies or non-routine events, which are outside normal operations but may occur unexpectedly, such as:Fires or explosions.

Chemical leaks.

Power failures.

Natural disasters.

Equipment breakdowns.

Maintenance tasks.

New projects.

These situations can create different or additional risks, making it crucial to identify them and prepare effective preventive or response measures. This can be done by:

Reviewing past incidents involving such situations.

Consulting with relevant experts.

Conducting scenario planning.

Developing emergency procedures and assigning roles.

Characterizing Hazards, Identifying Interim Controls, and Prioritizing:

After identifying hazards, it’s necessary to describe their nature, implement temporary fixes, and prioritize them for action.

Characterizing hazards involves describing their sources, forms, effects, and severity to assess the likelihood and seriousness of potential harm, considering factors like:Frequency of occurrence.

Duration of exposure.

Intensity of the hazard.

Probability of harm.

Severity of potential harm.

Implementing interim controls means taking short-term actions to reduce risk while waiting for permanent solutions, including:

Isolating or removing the hazard.

Providing PPE.

Posting warnings.

Implementing administrative controls like limiting exposure.

Providing safety training.

Prioritizing hazards for control involves ranking them by risk level and urgency, helping allocate resources effectively based on:

Legal compliance.

Worker concerns.

Cost-benefit analysis of control measures.

The hierarchy of controls (e.g., elimination is preferred over PPE).

Note: Many hazards are easily identified using common knowledge. For example, broken railings or frayed wires are easily spotted and fixed. Trained workers are excellent resources for hazard identification.

Good Safety Practices

Good safety practices are actions taken to prevent workplace accidents and injuries, creating a safer and healthier environment.

Conduct Regular Safety Training: Cover hazard identification, PPE use, and emergency response.

Encourage Hazard Reporting: Create a comfortable system for reporting hazards, and promptly investigate all reports.

Provide Appropriate PPE: Ensure workers have and know how to use the correct protective equipment for their tasks.

Maintain Equipment and Facilities: Regularly inspect and maintain equipment and facilities, and have a system for reporting and fixing unsafe conditions.

Cultivate a Safety Culture: Create a workplace where employees feel valued, comfortable raising safety concerns, and not afraid to address risks.

Hold Regular Safety Meetings: Discuss safety issues, reinforce the importance of safety, and share updates on hazards or procedures.

Enforce Safety Rules Consistently: Ensure safety rules are followed fairly to protect everyone.

Offer Safety Incentives: Reward employees for good safety records to encourage safety consciousness.

Celebrate Safety Achievements: Recognize and celebrate efforts that improve safety to reinforce its importance.

Prioritize Safety: Make safety a top priority by providing necessary resources and support.

Get in Touch

(+256) 790 036 252

(+256) 748 324 644

Info@nursesonlinediscussion.com

Kampala ,Uganda

© 2025 Nurses online discussion. All Rights Reserved Design & Developed by Opensigma.co